- DETAILS

- OPTIONS

- PHOTOS

- VIDEOS

|

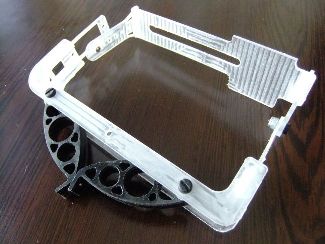

It has a net cutting area of 300 x 500 mm and a bridge – table distance of 135 mm. It is used for advertising, military and defense industry, electronic, pantography, photography, jewelry and hobby purpose. Also can produce 400 x 600, 600 x 600

|

|

|

Standard features of MINICNCs;

- Net cutting area 300 x 500, 400 x 600

- Distance between table and bridge is 80 mm and 135 mm (two model)

- “T” slotted eloxal coated aluminum table

- Body formed with sigma profiles

- Ball screws on all axes

- Drive with step motor and drivers

- 1 Hp. - 3 Hp 24.000 rpm spindle

- Cutting speed of 12 m/minute

- Manual control arms

- Electric panel

You can see the lines cut, being cut or to be cut with different colors on the main simulation screen and monitor the cutting operation from different angles. You can start the project from any desired point. You can continuously monitor the total cutting time and remaining cutting time on the screen. There are three motion options; step-by-step, slow and fast. You can move the machine from any desired point at any desired speed by entering numerical values. Cooling liquid and spindle can be opened and closed automatically in the beginning and ending of the cutting. You can smoothly use the machine with all Cad-Cam software. The operating system software is under the possession of our company and provided to your with license. |

|

It has a net cutting area of 300 x 500 to 400 x 600 mm and a bridge – table distance of 135 mm. It is used for advertising, electronic, pantography, photography, jewelry and hobby purpose.

|

|

|

|

| -ops01- |

|

|

|

| -ops02- |

|

|

|

| -ops03- |

|

|

|

| -ops04- |

|

|

|

| -ops05- |

|

|

|

| -ops07- |

|

|

|

| -ops08- |

|

|

|

| -ops13- |

|

|

|

| -ops21- |

|

|

|

|

| -MN00- |

|

|

|

| -MN01- |

|

|

|

| -MN02- |

|

|

|

| -MN03- |

|

|

|

| -MN04- |

|

|

|

| -MN05- |

|

|

|

| -MN06- |

|

|

|

| -MN07- |

|

|

|

| -MN08- |

|

|

|

| -MN09- |

|

|

|

| -MN10- |

|

|

|

| -MN11- |

|

|

|

| -MN12- |

|

|

|

| -MN13- |

|

|

|

| -MN14- |

|

|

|

| -MN15- |

|

|

|

| -MN16- |

|

|

|

| -MN17- |

|

|

|

| -MN18- |

|

|

|

| -MN19- |

|

|

|

| -MN20- |

|

|

|

| -MN21- |

|

|

|

| -MN22- |

|

|

|

| -MN23- |

|

|

|

| -MN24- |

|

|

|

| -MN25- |

|

|

|

| -MN26- |

|

|

|

| -MN27- |

|

|

|

| -MN28- |

|

| |

|

|

|

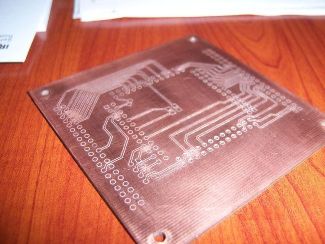

V1-Copper machining.

1 Hp. 24.000Rpm. |

|

|

|

V2-Glass machining

1 Hp. 24.000Rpm, with tungsten carbide tool. |

|

|

|

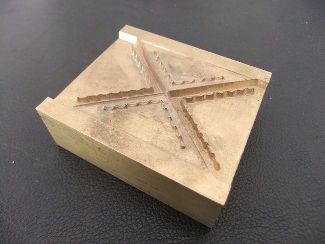

V3-Steel machining

1 Hp. 24.000 Rpm, |

|

|

|

|