|

|

|

|

Türkçe / English

|

|

Mainpage | Products

PATTERN PRODUCT CNC

PATTERN PRODUCT CNC

|

|

|

- DETAILS

- OPTIONS

- PHOTOS

- VIDEOS

|

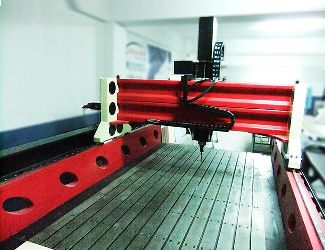

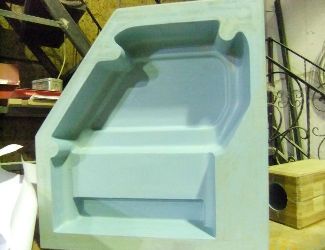

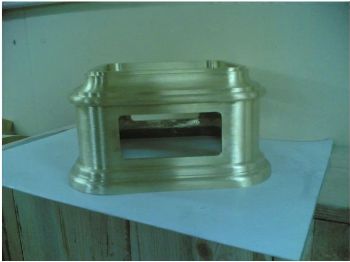

These are the machines that we manufacture to contribute to PATTERN PRODUCTION. Their bodies are manufactured by joint welding using ST-37 and ST-52 steel material and processed after welding stress is relief operation.

eurocnc Pattern Product CNCs are highly economic considering their features.

|

|

|

STANDARD FEATURES OF MACHINE MODEL CNCs:

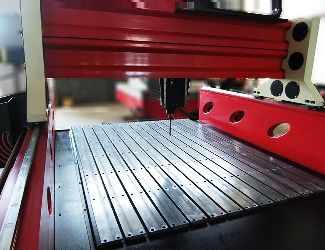

- 1000 x 1000, 1500 x 2000, 1500 x 3000 net cutting area dimensions.

- Distance between table top and bridge is 600 mm.

- 2 ball screws in the “Y” axis and 1 ball screw in the “X” and “Z” axes.

- Single piece aluminum cast bridge

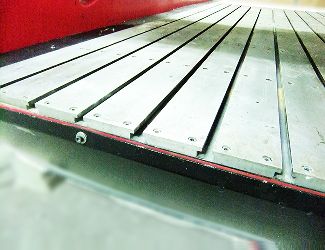

- “T” slotted steel table

- 7.5 Hp. 24.000 rpm semi-automatic spindle

- FAGOR or SYNTEC CNC control unit

- Hand-wheel

- Speed up to 30 m/minute

- 3D material processing

- Servo motor with brake on the “Z” axis

- Backlash-free planetary gear unit on all axes

- Body pained with epoxy paint

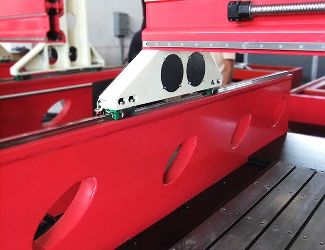

The bridge is moved by 2 servo motor located on each side of the bridge. In one of the servo motors stops for any reason, a difference will occur between the right and left side of the bridge therefore PLC which continuously controls this situation stops the machine thus prevents both work piece and machine from being damaged. |

|

|

| -ops01- |

|

|

|

| -ops02- |

|

|

|

| -ops03- |

|

|

|

| -ops04- |

|

|

|

| -ops05- |

|

|

|

| -ops06- |

|

|

|

| -ops07- |

|

|

|

| -ops08- |

|

|

|

| -ops09- |

|

|

|

| -ops10- |

|

|

|

| -ops11- |

|

|

|

| -ops12- |

|

|

|

| -ops13- |

|

|

|

| -ops14- |

|

|

|

| -ops15- |

|

|

|

| -ops16- |

|

|

|

| -ops17- |

|

|

|

| -ops18- |

|

|

|

| -ops19- |

|

|

|

| -ops20- |

|

|

|

| -ops21- |

|

|

|

|

| -MD01- |

|

|

|

| -MD02- |

|

|

|

| -MD03- |

|

|

|

| -MD04- |

|

|

|

| -MD05- |

|

|

|

| -MD06- |

|

|

|

| -MD07- |

|

|

|

| -MD08- |

|

|

|

| -MD09- |

|

|

|

| -MD10- |

|

|

|

| -MD11- |

|

|

|

| -MD12- |

|

|

|

| -MD13- |

|

|

|

| -MD14- |

|

|

|

| -MD15- |

|

|

|

| -MD16- |

|

|

|

| -MD17- |

|

|

|

| -MD18- |

|

|

|

| -MD19- |

|

|

|

| -MD20- |

|

|

|

| -MD21- |

|

|

|

| -MD22- |

|

|

|

| -MD23- |

|

|

|

| -MD24- |

|

|

|

| -MD25- |

|

|

|

| -MD26- |

|

|

|

| -MD27- |

|

|

|

| -MD28- |

|

|

|

| -MD29- |

|

|

|

| -MD30- |

|

|

|

| -MD31- |

|

|

|

| -MD32- |

|

|

|

| -MD33- |

|

|

|

| -MD34- |

|

|

|

| -MD35- |

|

|

|

| -MD36- |

|

|

|

| -MD37- |

|

|

|

| -MD39- |

|

|

|

| -MD40- |

|

|

|

| -MD41- |

|

|

|

| -MD42- |

|

|

|

| -MD43- |

|

|

|

| -MD44- |

|

|

|

| -MD45- |

|

|

|

| -MD46- |

|

|

|

| -MD47- |

|

|

|

| -MD48- |

|

|

|

| -MD49- |

|

|

|

| -MD50- |

|

|

|

| -MD51- |

|

|

|

| -MD52- |

|

|

|

| -MD53- |

|

|

|

| -MD54- |

|

|

|

| -MD55- |

|

|

|

| -MD56- |

|

|

|

| -MD57- |

|

|

|

| -MD58- |

|

|

|

| -MD59- |

|

|

|

| -MD60- |

|

|

|

| -MD61- |

|

|

|

| -MD62- |

|

|

|

| -MD63- |

|

|

|

| -MD64- |

|

|

|

| -MD65- |

|

|

|

| -MD66- |

|

|

|

| -MD67- |

|

|

|

| -MD68- |

|

|

|

| -MD69- |

|

|

|

| -MD70- |

|

|

|

| -MD72- |

|

|

|

| -MD74- |

|

|

|

| -MD75- |

|

|

|

| -MD76- |

|

|

|

| -MD77- |

|

|

|

| -MD78- |

|

|

|

| -MD79- |

|

|

|

| -MD80- |

|

|

|

| -MD81- |

|

|

|

| -MD82- |

|

|

|

| -MD83- |

|

|

|

| -MD84- |

|

|

|

| -MD85- |

|

|

|

| -MD86- |

|

| |

|

|

|

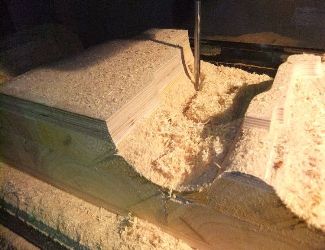

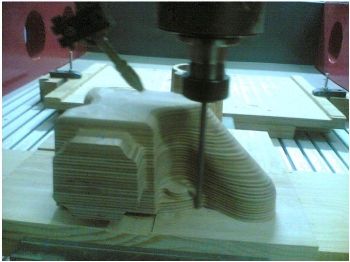

V1-Wood pattern, rough machining.

12mm endmill, 12.000 rpm. |

|

|

|

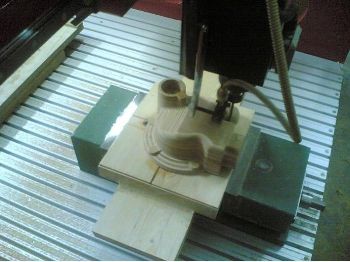

V2-Wood pattern, finish machining.

6mm spherical tool, 18.000 rpm. |

|

|

|

V3-Dimension control machining

12 Hp 12.000 rpm. water cooling spindle. BT40 tool, Alüminium. |

|

|

|

V4-Reference pin hole drilling

6mm. endmill, 5083 quality aluminium. 8mm. Hole drilling with 6mm toll. Spindle is 24.000 Rpm. |

|

|

|

V5-Pocket machining.

Pocket machining with interpolation. The Tool is 8mm. endmill, 5083 quality aluminium. 24.000 Rpm. |

|

|

|

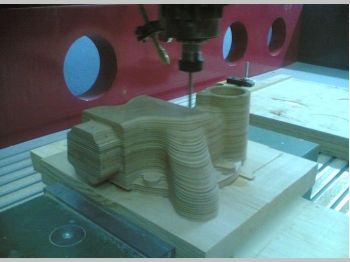

V6-Wood pattern, rough machining.

Rough machining with 12mm. endmill. |

|

|

|

V7-Alüminium machining.

Face machining with 50mm. tool |

|

|

|

V8-Alüminium pattern machining.

Pattern edge machinig to 5083 quality aluminium. The tool is 8 mm endmill. |

|

|

|

V9-R3 aluminium finish machining.

Pattern finish machinig to 5083 quality aluminium. The tool is R3. |

|

|

|

|

|

|

|